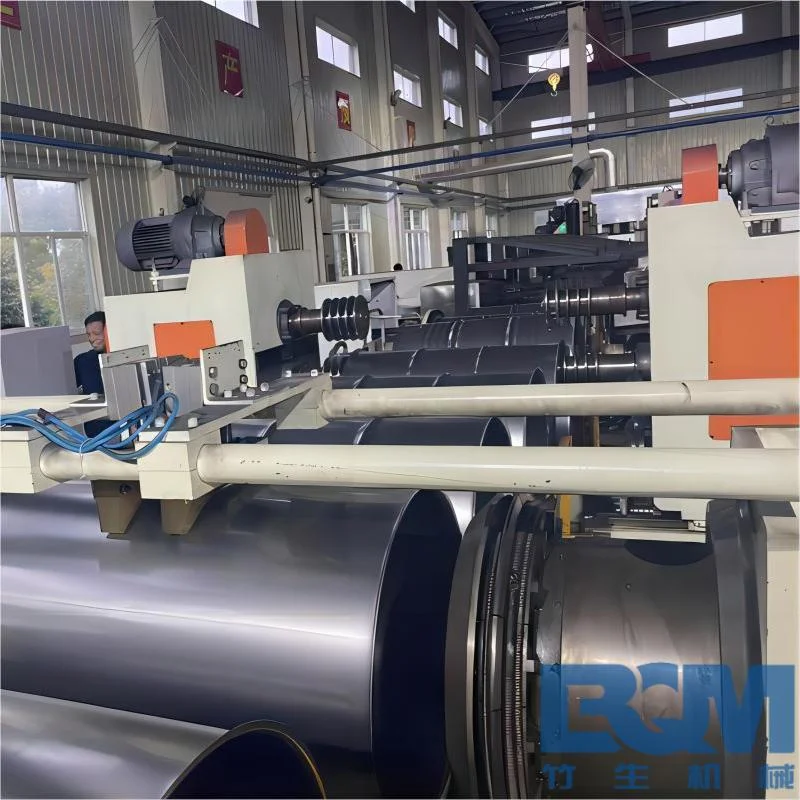

The Steel Drum Flanging & Corrugating Machine shapes steel drums by crimping and forming their edges. It’s vital for creating the distinctive fluted pattern seen on drum bodies.

1.Production program

(1). Production cycle: 12 barrels/minute for barrels and 12 pieces/minute for finished products.

(2). Workpiece barrel frame diameter: Φ571.5mm, Φ560mm.

(3).Steel plate specifications: Thickness is 0.8-1.2mm; length is 850-1000mm.

(4). Steel plate material: SPCC, Q195-215A.

(5). Conveying method: Vertical conveying, depending on the form of the host machine.

(6). Energy: Power supply: meets TN-S system.

(7).Conveying elevation: 1050mm

(8). Steel drum appearance requirements:

a: Ordinary stretching

b: Ordinary muscle expansion + 4 ripples

c: W rib + no corrugation

d: W ribs + 3 corrugations

e: W ribs + 4 corrugations

f: W ribs + 5 corrugations

Note: After processing and forming, the barrel frame cannot be out of round (the roundness tolerance of the barrel ring is ≤±2mm, and the height tolerance of the barrel ring is ±1mm).

(1)GBS0054-95: The power configuration in the workshop shall comply with the “Low Voltage Power Distribution Design Code”.

(2)GBJ87: Noise control design standard.

(3) GB502318: General specifications for construction and acceptance of mechanical equipment installation projects.

(4)JB160: Design specifications for environmental protection in the machinery industry.

1) Equipment production capacity: maximum 720 barrels/hour

2) Production rhythm: 8-12 pieces/minute (can be adjusted as needed).

3) Barrel frame diameter: Φ571.5mm, Φ560mm.

4) Steel plate specifications: thickness: 0.8-1.2mm, length: 850mm-1000mm.

5) The power distribution cabinet adopts a single machine and a single cabinet, with full chain control.

6) The main electrical components are SIEMENS S7-1500 PLC, SIEMENS contactor, circuit breaker, frequency converter, SEW servo and reducer. Hydraulic components adopt Yuyan brand.

Medium Speed Horizontal Type:

The drum will be loaded to the machine automatically through conveyor, the machine will automatically check the drum body and lift it to a suitable places, then the carriage plate will move forward, the drum body will be flanged and expanded, then automatically lift down, the carriage plate will automatically move back(when the carriage plate is back, the machine decompression will be loading state, which will save energy). The drum body will go down and be unloaded on the conveyor.

Machine size: 3800*710*1600mm

Machine weight: 5000kgs

Power: 18KW

Capacity:>6pcs/min

steel drum flanging & corrugating machine

steel drum flanging & corrugating machine

Customer Site Installation & Commission

FAQ:

Headquartered in Changzhou, China, BQM has been selling to the domestic market (65.00%), Southeast Asia (15.00%), Eastern Europe (10.00%), and South Asia (10.00%) since 1995. Now BQM has the full technology and manufacturing capability for Steel Drum Production Line, Steel Drum Filling Line, Steel Drum Reconditioning Line and the matching packing machinery.

Pre-production samples before mass production;

Final inspection before shipment;

Accept inspection by third-party agencies or customers before shipment.

All types of steel drum production line, all-steel drum filling line, IBC tank-plastic container production line and other customized steel-plastic container production lines.

Accepted delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDU, DDP, DAP, Express;

Accepted payment currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF;

Accepted payment types: T/T, L/C, D/P, D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

Building 5, ABBY Nail, Tianning District, Changzhou City, Jiangsu Province, China Postcode: 213014

©2024 Best Quality Machinery Teknik Co.,Ltd